Unveiling the Manufacturing Secrets: Inside the Bible Factory and the Art of Custom Engraved Bibles

- Joy Creative Bibles

- Feb 14

- 3 min read

Captivating Start

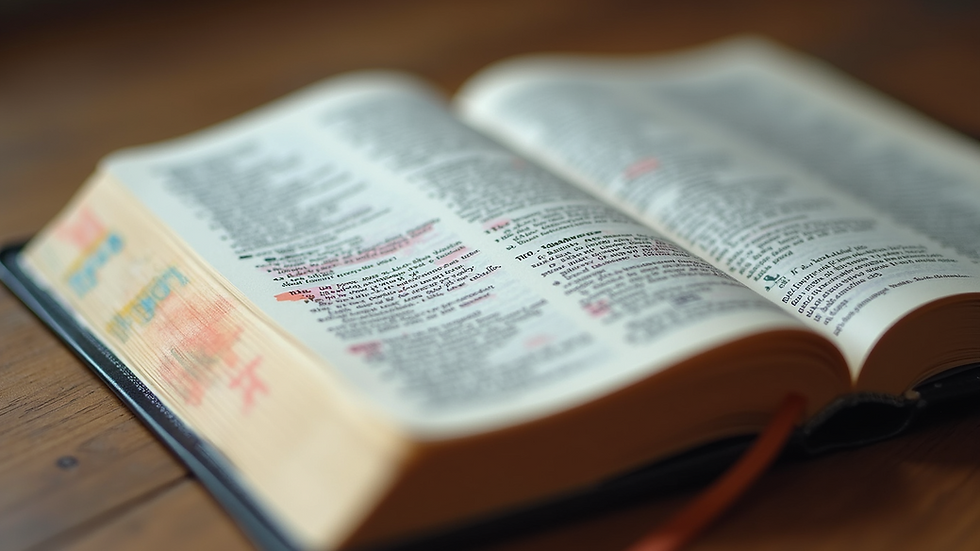

Have you ever paused to think about how the cherished Bibles we hold in our hands come to be? The journey from concept to creation is a mix of history, technology, and meticulous artistry. The rise of custom engraved Bibles adds a personal touch to these sacred texts, making it even more important to explore the manufacturing processes behind them. Let's embark on a journey to uncover the fascinating world of Bible production and see how unique features transform them into treasured keepsakes.

The Process of Bible Production

The journey to creating a Bible begins with selecting top-notch materials. High-quality paper, leather, cloth, and synthetic options are all considered. For example, publishers often choose paper that is 32-36 g/m² for durability and opacity, ensuring that ink doesn’t bleed through.

Manufacturers establish relationships with reliable suppliers to secure these materials. When crafting a Bible, the feel and durability are central to the customer experience. Choosing the right components is crucial to delivering a product that is both stunning and long-lasting.

Types of Bibles

Among the diverse range of Bible types, specific styles cater to different preferences and needs. Here are some popular categories:

Standard Editions: These Bibles focus on clarity of text, ideal for daily reading. Many are available in various translations, such as the New International Version (NIV) or King James Version (KJV).

Study Bibles: Packed with annotations, maps, and commentary, these Bibles provide insights that deepen understanding. For instance, the ESV Study Bible includes over 20,000 notes and articles.

Custom Engraved Bibles: Offering a personal touch, these Bibles feature engravings on their covers. They're perfect for marking special occasions, such as graduations or weddings, and can command a price increase of up to 30% compared to standard editions.

Each of these types has unique requirements that shape their production processes. As custom engraved Bibles grow in popularity, manufacturers adapt their methods to meet this demand efficiently.

The Printing Harmony

With materials selected, the printing phase commences. High-quality offset or digital printers produce the text with precise clarity, often achieving resolutions up to 1200 dpi for crisp letters. The choice of printing method depends on demand; for instance, digital printing suits smaller runs, while offset is preferred for larger volumes.

Post-printing, pages undergo stringent quality control. Issues are identified quickly—studies show that an inspection can reduce defects by as much as 80%. Ensuring flawless printing is vital because even tiny errors can affect readability.

Binding and Finishing Techniques

Once printing is complete, the binding stage begins. Bibles can be bound using hardcover, softcover, or genuine leather techniques. For instance, a hardcover Bible might use a method called cloth spine binding, adding durability that appeals to many readers.

In custom engraved Bibles, specialized techniques are used to imprint designs on the cover without compromising quality. Finishing touches, such as gilded edges or embossing, can increase perceived value; studies suggest these features might enhance customer satisfaction by up to 40%.

The Engraving Process

The engraving process breathes uniqueness into custom Bibles. Personalization can range from names to scripture verses, making each piece special. Techniques like laser engraving can offer precision, while foil stamping provides a glossy finish that stands out.

It's crucial to carefully plan engravings to ensure they do not interfere with the Bible’s binding or printing. Correct depth and clarity are vital; successful engravings should last, maintaining their beauty for years to come.

Quality Assurance

Before reaching the customer, each Bible goes through a rigorous quality assurance phase. Every aspect, from page alignment to engraving quality, is thoroughly checked. This final step is essential to maintain the high standards expected by consumers.

If inconsistencies are discovered, corrective measures are put in place. For instance, about 5% of products may need to be reworked in high-production environments, ensuring that only the highest quality items are delivered.

Packaging and Distribution

After passing quality checks, Bibles are beautifully packaged, enhancing the unboxing experience. Protective materials are employed to prevent any damage during shipping.

Bibles are sent to various destinations, including retail stores and individual consumers, reaching diverse communities worldwide. This final step not only signifies the end of production but also emphasizes the purpose of the Bible: to inspire faith and connection among people.

In Closing

The journey of Bible manufacturing is a remarkable story of tradition, skill, and adaptation. From carefully selecting materials to implementing modern printing and binding techniques, each step contributes to creating an exceptional product.

As the desire for custom engraved Bibles grows, the industry thrives by embracing personalization. Every engraved Bible becomes more than just a book; it transforms into a heartfelt treasure, ready to be cherished for years to come.

Next time you hold a Bible, remember the intricate processes and countless hands that created it. Each Bible is a symbol of faith, tradition, and a deeper personal connection to our beliefs.

Comments